- Wearth Group

- Our divisions

- Our expertise

- Turnkey marinas

- Docks & accessories for harbors and marinas

- Floating rotomolded accessories

- Industrial rotomolded accessories

- Marina management

- Waterfront Development

- Custom floating projects

- Floating solar platforms

- Floating solar farm

- Tackling marine pollution

- Aluminum bridges and structures

- Self-watering planters

- Careers

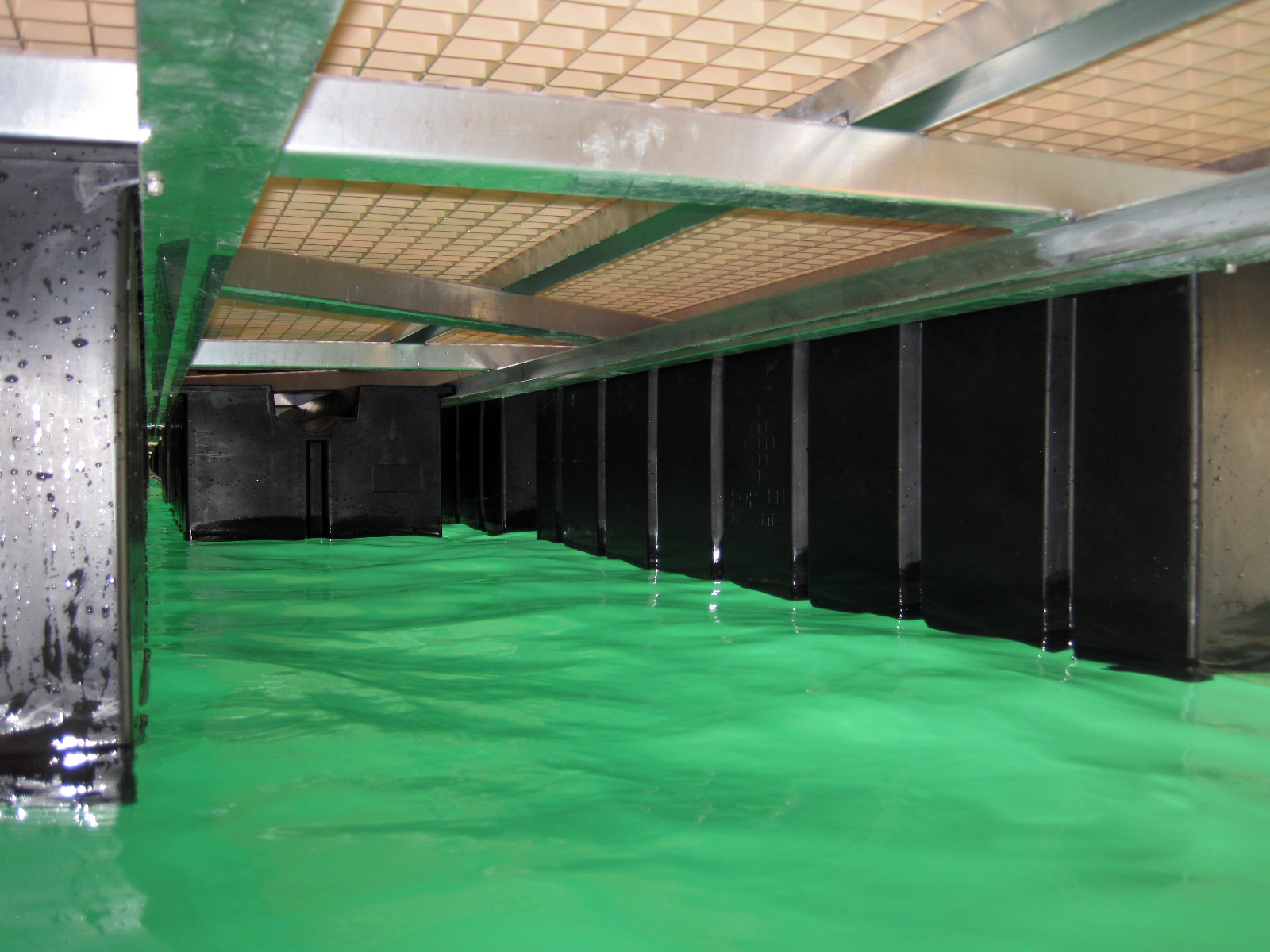

Rotomolding is a thermoplastic processing technique used to create hollow pieces with no seam. It can be used to produce highly technical components of all shapes and colors. Rotomolding is also an eco-friendly process, as it produces no material waste and all material can be 100% recycled.

3

floating ranges

Ranges of floating accessories with multiple applications

We specialize in thermoplastic rotomolding, a technique we use instead of more common processes such as blow-molding and thermoforming.

All of our products are made in France in our factory in Ain.

Since 1999, we have manufactured the equivalent of 150,000 metric tons of floating components for use in harbor and pleasure boating structures all over the world.

Our decades of experience make us a leading manufacturer of nautical products and accessories.

We provide effective solutions for applications in a broad range of sectors and offer high-quality products, including for floating homes and road markers, for events with our range of modular docks, and for the maritime world, including our wide range of buoys and floats.

Use cases

OUR SOLUTIONS

Our ranges of accessories

Rotomolded accessories for a range of applications: leisure, industry, floating homes

Buoys - Markers, mooring

Floats - Docks, floating homes

Modular docks - Leisure, industry

Rotomolding techniques provide a high level of adaptability when producing new accessories

We offer this expertise through our company

Rotax marine

1999

25 years of expertise

150 000

Tonnes of floating elements

1

Production plant

5

Continents